Materials Used for Facial Bone Implants or reconstruction

- Dr. Park

- Oct 13, 2024

- 2 min read

Updated: Oct 17, 2024

The materials used for facial bone implants include Bone Cement (PMMA), Silicone, PEEK, Titanium, Gore-Tex, and PCL.

Currently, the materials approved for insertion into the human body from 3D-printed implants are PEEK, Titanium, and PCL.

Titanium

Titanium has excellent biocompatibility with the human body, and its strength and durability allow for long-term use. Additionally, titanium does not transmit radiation, making it clearly visible in X-rays and CT scans, which is very useful for monitoring post-operative progress. However, titanium is costly to produce compared to other metals, and there may be distortion in imaging due to radiation scattering.

Bone Cement (PMMA) and Silicone

Bone Cement (PMMA) and silicone are primarily produced using a mold-based method. It is possible to print molds using a 3D printer and then inject materials into these molds to create implants. However, the technology to directly print these materials using a 3D printer is still under development and has not yet been commercialized in South Korea.

PCL(Polycaprolactone)

PCL is a biodegradable material that decomposes over time within the body. However, it is not an osteoinductive material, so it must be used in conjunction with autologous bone to facilitate bone formation. Similar to "guided bone regeneration" in dentistry, PCL is primarily used as an adjunct in facial bone reconstruction. PCL typically begins to decompose within 2 to 3 years, during which autologous bone fills the area.

PCL has a plastic-like feel and is weaker than bone. When used alone for the mandible, bone formation may be minimal, but when used with autologous bone or other bone graft materials, physiological bone formation is possible. This indicates that the area reacts to physiological changes, which may lead to differences in shape over time from the original plan.

In contrast, other inorganic implants, which are lifeless, tend to maintain their shape consistently within the human body.

PEEK(Polyetheretherketone)

PEEK is an engineering plastic that does not decompose and remains in the body. It possesses physical properties similar to bone and is typically manufactured in thicknesses and shapes comparable to bone. However, it has not yet received approval for use in mandibular reconstruction in South Korea, although it is applied for this purpose in China.

Radiation-Transmissive Materials

Except for titanium, materials like PEEK, PCL, silicone, Gore-Tex, and Medpor are radiation-transmissive. This means that they are not easily visible in X-rays or CT scans, although silicone(below image) is relatively distinguishable.

GMP (Good Manufacturing Practice) Certification

Implants inserted into the human body must be manufactured by companies that have obtained 3rd-grade medical device manufacturing certification (GMP). 3rd-grade medical devices are classified as high-risk medical devices that can significantly impact human health, and they must undergo strict safety and efficacy verification during the manufacturing process.

Custom Implant Production

The process of designing and producing custom implants using the patient's CT data is essential for creating personalized implants tailored to the patient's condition.

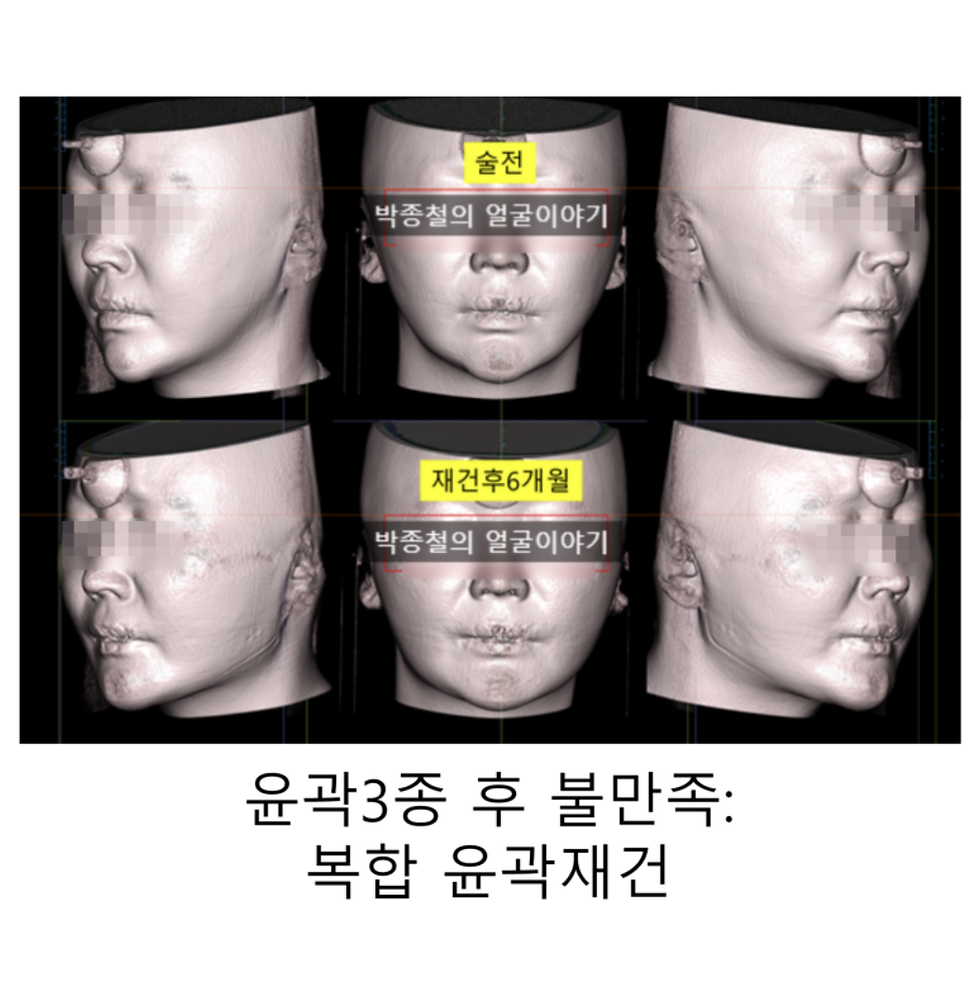

Below is an example of a patient-customized titanium implant.

Comments